Dye

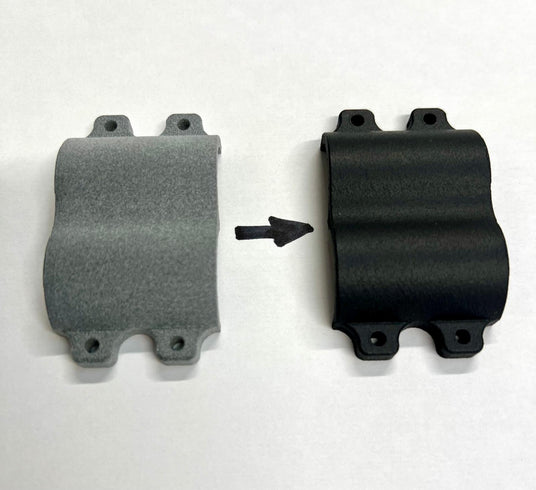

MJF Pa12 Nylon parts in their raw form are a light grey colour. This can be fine for use in internal parts. Most of the parts we provide to manufacturers though are post-dyed. The light grey surface is dyed through so if during the parts' life it is scratched the underlying material will also be black.

SLS parts from our 2nd Life material are white to Ivory in colour. They are readily dyed to a deep black.

MJF-Colour parts are not usually dyed but as it can print white it is a possibility.

The most usual colours that we run are black and gun metal grey but others can be provided on demand.

Polish (Polyshot)

Polyshot finishing is a fast and efficient surface finish that provides parts with a low lustre and pleasing surface texture. The vast majority of parts we make are dyed and then polished using this method.

Each part is bombarded with tiny plastic balls in an automated blast cabinet (ours is a DyeMansion Powershot S). The tiny balls impacting the surface will “harden off” the surface and give a good working finish while enhancing colours.

The Polyshot polish can also be applied to “raw” parts to achieve the same surface quality but where parts do not need to be dyed.

Vibro-Polish

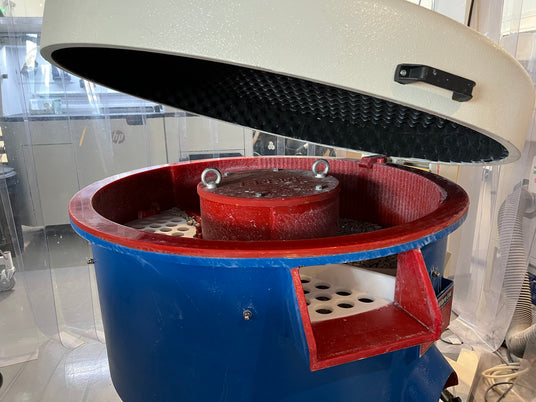

The 200L Vibro-polishing unit can be used for most parts except we would not recommend it for very fragile parts as it is a more aggressive process. “Vibro” will abrade parts to reduce any print artifacts and yield smoother parts. It is a subtractive process so can round sharp edges slightly.

We can work with you to provide strategies to protect delicate features from the the abrasive media

Vibro can be combined with other finishes, such as Vapour polishing and dyeing to yield spectacular results.

Vapour polish

Vapour polishing of Pa12 and Pa11 is carried out in house to our standards using our AMT PostPro3D. The large treatment volume of the PostPro3D allows us to get a high throughput and achieve great price points on parts that we print.

There are many advantages to vapour polishing printed parts. Aesthetics is the normal driver for most customers but there is other real world advantages. Re-flowing of the surface of printed parts will seal micro cracks that can be present either form the process of manufacturing or through cooling stresses. The sealing of these will increase the fatigue resistance of parts as well as the elongation at break. Reducing surface porosity will aid sealing for underwater applications and enhance painted surfaces.

Gold Standard Finishing

All printed parts are not created or finished even. Where superior mechanical properties or surface finishes are required Incremental-AM have invested years in refining multi-applicable finishing techniques to get HP MJF printed parts to near injection moulded levels of finish.

The part shown, is not hand sanded, painted or covered in any way.

Not all models are suitable for this process and this service is not offered through our website, you have to talk to a real person as it is a collaborative approach involving design input and finishing protocol development depending what is seeking to be achieved. The results though can be spectacular.

NB: the image is not a render!